The Puncture-Proof Moment That Changed My Mind About Safety Shoes

I never thought I’d be the guy preaching about safety footwear. Hell, for the first five years of my construction career, I was that jackass in discount store boots bragging about saving a few bucks. Then came what my crew now calls “The Nail Gun Incident of 2019.”

Let me tell you exactly how fast you can go from skeptic to evangelist when it comes to puncture-proof work shoes.

The Day My Old Boots Failed Me

It was a scorching July afternoon on a commercial renovation project in Phoenix. We were framing interior walls, and I was using a pneumatic nailer while balanced on a stack of 2x4s—not exactly OSHA-approved, but we’ve all been there.

One second I was securing a top plate, and the next I was hopping around on one foot, screaming obscenities that would make a sailor blush. A 3½-inch framing nail had misfired, ricocheted off a metal stud, and punched straight through the thin sole of my bargain boots and into my foot.

The ER doc who pulled that nail out didn’t mince words: “Half an inch to the left, and you’d have nerve damage. You got lucky, but luck runs out.”

Six weeks of limited duty, a nasty infection, and about $3,700 in out-of-pocket medical expenses later, I became the jobsite’s most vocal advocate for proper safety footwear.

The Mind-Blowing Science Behind Puncture Resistance

After my injury, I went down a rabbit hole researching puncture-proof technology. What I discovered blew my mind—and made me realize how foolish I’d been.

Most quality puncture-resistant shoes use one of two approaches:

- Steel midsole plates: Thin but incredibly strong steel sheets placed between the outsole and insole

- Composite/Kevlar layers: Flexible yet virtually impenetrable material similar to what’s used in bulletproof vests

The engineering behind these protective elements is fascinating. A properly designed puncture-resistant midsole can withstand over 1,200 Newtons of force—that’s roughly equivalent to a 265-pound object concentrated on a nail point.

Think about that for a second. That’s the difference between a normal Thursday and six weeks of painful recovery.

Beyond Just Puncture Protection: The Full Safety Package

My “conversion moment” focused me on puncture protection, but I quickly learned that truly effective safety shoes need to address multiple hazards simultaneously.

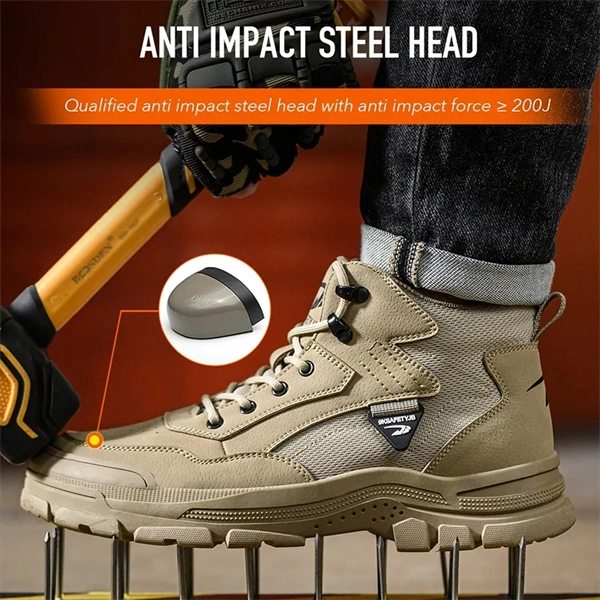

Steel Toe Protection: An Absolute Game-Changer

Two months after my return to work, I watched a 4×8 sheet of ¾-inch plywood slip from a stack and land edge-first on my coworker’s foot. The difference between his experience (protected by steel toes) and what could have happened was dramatic:

| Without Steel Toe | With Steel Toe |

| Potential broken metatarsals | Minor bruising |

| Weeks of recovery | Back at work next day |

| $1000s in medical bills | Zero medical costs |

| Possible permanent damage | No lasting effects |

That’s when I realized: proper safety footwear isn’t an expense—it’s an insurance policy for your livelihood.

The Waterproof Factor: Not Just About Comfort

Working in the Southwest, I initially dismissed waterproofing as unnecessary. Then came a commercial plumbing job where a pipe burst, flooding the work area with two inches of water. Those with waterproof boots kept working; the rest of us ended the day with trench foot and fungal infections that lingered for weeks.

Modern waterproof membranes like GORE-TEX® and similar technologies create a fascinating barrier: they block water molecules while allowing smaller vapor molecules (sweat) to escape. It’s not just marketing hype—it’s legitimate materials science that protects your health.

The Impossible Balance: Lightweight Yet Protective

The biggest objection I hear from fellow tradespeople is: “Yeah, but safety shoes are too heavy/clunky/uncomfortable.”

Five years ago, they’d have been right. Today? That excuse doesn’t fly.

Modern safety footwear has undergone a revolution in materials science. Composite materials, advanced polymers, and smart design have created options that offer full protection while weighing 30-40% less than traditional safety boots.

My current everyday work shoes weigh 1.2 pounds per boot—about the same as a quality hiking shoe—while offering steel toe protection, puncture resistance, and waterproofing. The difference in end-of-day fatigue is remarkable.

Not Your Daddy’s Clunky Work Boots: The Style Evolution

Let’s address the elephant in the room: most guys avoid safety footwear partly because traditional options look like something your grandfather would wear.

The aesthetics of safety shoes have evolved dramatically. My current rotation includes styles that could easily pass for casual sneakers or hiking shoes at first glance. This matters more than you might think—because footwear you’re actually willing to wear consistently is footwear that can protect you.

The color options, sleeker profiles, and modern materials make today’s safety shoes something you might actually want to wear, not just something you have to wear.

Real-World Performance: Where The Rubber Meets The Road

In the three years since my “conversion,” I’ve worn my puncture-proof safety shoes across a variety of challenging environments. Here’s what I’ve learned about where they truly shine:

- Demolition sites: Where nails, screws, and metal fragments create a minefield for unprotected feet

- Roofing jobs: Where dropped fasteners create instant puncture hazards

- Commercial renovations: Where you never know what’s hiding beneath old flooring

- Mechanical rooms: Where tight spaces and overhead work create unique foot hazard zones

- Landscaping: Where buried objects often lurk beneath soil and mulch

The Cost-Benefit Analysis Every Tradesperson Should Consider

Let’s talk money, because that’s often the sticking point. Quality puncture-proof safety shoes typically range from $120-200—significantly more than the $40-60 bargain options.

But consider this breakdown from my personal experience:

| Expense Category | Without Safety Shoes | With Quality Safety Shoes |

| Initial footwear cost | $50 (replaced 3x yearly) | $150 (replaced annually) |

| Work days missed due to injury | 30 days in 5 years | 0 days in 3 years |

| Medical expenses | $3,700+ out of pocket | $0 |

| Productivity impact | Significant | Minimal |

| Peace of mind | Nonexistent | Priceless |

When I do the math, my “expensive” safety shoes have saved me thousands of dollars and countless headaches. That’s not marketing—that’s my bank account and personal health.

Addressing Common Questions & Concerns

FAQ: What Working People Actually Want to Know

Q: How much does puncture resistance affect comfort and flexibility?

A: With older designs, significantly. With modern safety shoes, the difference is minimal. My current pair has a flexible Kevlar puncture-resistant layer that I barely notice while working. The slight reduction in sole flexibility is a worthwhile tradeoff for knowing I won’t be visiting the ER if I step on a nail.

Q: Do waterproof work shoes make your feet sweat more?

A: It depends entirely on the breathability factor. My first pair of waterproof boots were like personal foot saunas. Current models with proper breathable membranes and mesh uppers actually keep my feet drier throughout the day than non-waterproof options, even in 100°F Arizona heat.

Q: How long does the puncture protection actually last?

A: In my experience, steel midsole plates maintain their protection indefinitely, while composite/Kevlar layers maintain effectiveness for about 12-18 months of daily wear. The key is inspecting your outsoles regularly—once they show significant wear, the protection layer could be compromised.

Q: Are steel toes uncomfortable for all-day wear?

A: Old-school steel toes? Absolutely uncomfortable. Modern designs with properly shaped toe boxes? I forget they’re there within minutes. The key difference is toe box volume and proper sizing—a well-designed steel toe cap shouldn’t contact your toes at all.

The Ultimate Test: Would I Recommend These to My Own Son?

My oldest started his apprenticeship last year. The very first thing I bought him was a pair of quality puncture-proof, steel toe, waterproof work shoes.

Not because I’m paranoid, but because I’ve lived both sides of this story. I’ve worked with and without proper protection. I’ve felt that sickening moment when you realize you’ve been seriously injured, and I’ve experienced the confidence that comes from knowing your feet are properly protected.

The choice isn’t really a choice at all if you value your health, livelihood, and longevity in the trades.

Making the Switch: What to Look For

If you’re convinced (or at least curious) about upgrading your work footwear, here are the non-negotiable features I recommend based on hard-earned experience:

- Legitimate puncture resistance – Look for ASTM F2413-18 or similar certification

- Properly rated steel or composite toe – Should meet or exceed ANSI Z41 PT91 standards

- Waterproof membrane with breathable design

- Weight under 1.5 lbs per shoe – Heavier options cause unnecessary fatigue

- Shock-absorbing midsole – Your back will thank you after concrete-slab days

Don’t compromise on these features. Your future self will thank you.

From Skeptic to Believer: My Final Thoughts

I started this journey as the guy making fun of “safety sam” types who “wasted money” on expensive work shoes. Now I’m the passionate advocate telling every new person on site about the importance of proper foot protection.

It only takes one incident—one stray nail, one dropped tool, one misstep—to change everything. Don’t learn this lesson the painful way like I did.

Invest in quality puncture-proof safety shoes that offer comprehensive protection. Your feet carry you through every workday and support your livelihood. Protect them accordingly. 🔨👷♂️

[Ready to upgrade your work footwear? Check out our selection of puncture-proof safety shoes engineered for real-world protection →]