Nails, Debris, Slippery Floors: How My Sneakers Conquered It All

Introduction: The Unsung Heroes on Our Feet

We seldom give much thought to the humble sneakers that shield our feet from the world’s hazards. Yet these engineered marvels stand between us and a multitude of dangers lurking on every surface we traverse. My personal odyssey with high-performance footwear began after a series of unfortunate incidents that left me questioning the very foundations of shoe design. The journey transformed my understanding of what truly exceptional footwear can accomplish when faced with nails, debris, and treacherously slippery floors.

The Evolution of Protective Footwear

From Primitive Coverings to Modern Marvels

The archeological record indicates that humans have been protecting their feet for approximately 40,000 years. Early hominids wrapped animal hides around their feet, secured with rudimentary lacing systems. These nascent designs eventually evolved into the specialized footwear of ancient civilizations. Egyptian sandals featured papyrus and palm leaves, while Roman caligae incorporated hobnailed soles for improved traction on varied terrains. The progression from these antediluvian designs to contemporary sneakers represents one of humanity’s longest-running product development cycles.

The Scientific Revolution in Shoe Design

The true metamorphosis in protective footwear emerged in the mid-20th century. Polymeric chemistry revolutionized sole construction, while biomechanical research transformed our understanding of foot dynamics. Engineers began implementing abrasion-resistant compounds and puncture-proof layers. Vulcanized rubber gave way to polyurethane composites and ethylene-vinyl acetate foams. These advancements created foundations for the modern sneaker’s remarkable protective capabilities. Manufacturers started incorporating aramid fibers—the same materials used in bulletproof vests—into the soles of high-performance shoes. The humble sneaker had become a technological marvel.

My Journey to Finding the Perfect Pair

Initial Frustrations with Inadequate Footwear

My personal quest began ignominiously. I had purchased discounted athletic shoes that promised “all-terrain performance” at a fraction of premium prices. These ersatz sneakers failed spectacularly during my first renovation project. A protruding nail penetrated the thin sole, narrowly missing my foot but destroying the shoe. Subsequent pairs proved equally disappointing. One disintegrated after minimal exposure to construction debris. Another became perilously slick on wet surfaces, resulting in a near-catastrophic fall. My frustration mounted with each failed pair.

The Discovery That Changed Everything

Serendipity intervened during a conversation with a construction worker. He gestured toward his feet, where he wore what appeared to be ordinary athletic shoes. “These have saved me countless times,” he explained, revealing they were specialized cross-trainers with protective elements borrowed from safety footwear. The revelation prompted extensive research into hybrid sneaker designs. I discovered an entire subcategory of footwear that combined athletic performance with industrial-grade protection. My subsequent purchase—a pair of composite-soled trail runners with hydrophobic uppers—marked the beginning of my footwear enlightenment.

Anatomy of a Superior Sneaker

Outsole Technology: The First Line of Defense

The outsole constitutes the primary interface between foot and environment. Exceptional protective sneakers feature multi-compound outsoles with differentiated zones of hardness. The forefoot might incorporate softer, high-traction materials, while the heel employs denser compounds for durability. Lug patterns vary dramatically based on intended use, with self-cleaning designs preventing debris accumulation. The most advanced models utilize siping—microscopic cuts in the rubber that create additional edges for grip on wet surfaces. These seemingly minor details make extraordinary differences in real-world performance.

Midsole Construction: Balancing Cushion and Resilience

Between outsole and foot lies the critical midsole layer. This component must simultaneously provide cushioning, stability, and protection. Modern protective sneakers often incorporate dual-density foam systems—softer compounds for impact absorption surrounded by firmer materials for structural integrity. Some incorporate thermoplastic plates or carbon fiber shanks that prevent punctures while maintaining flexibility where needed. The midsole represents the sneaker’s cerebral cortex, processing and responding to ground forces in milliseconds.

Upper Materials: Durability Meets Comfort

The upper portion envelops the foot in protective materials without restricting movement. Advanced sneakers employ ripstop nylon, Kevlar-reinforced mesh, and abrasion-resistant synthetics. Water-repellent treatments maintain breathability while shedding moisture. Strategic overlays reinforce high-wear areas without adding unnecessary bulk. The best designs incorporate these protective elements invisibly, creating shoes that perform like armor but wear like slippers. The confluence of protection and comfort represents the pinnacle of sneaker engineering.

Conquering Construction Hazards

How Puncture-Resistant Soles Saved My Feet

The first true test of my new footwear occurred during a home renovation project. While dismantling shelving, I stepped directly onto a protruding nail. Instead of the expected pain, I felt only pressure. Examining my sole revealed the nail had penetrated the outer rubber but stopped completely at the internal protective layer. This composite shield—a sandwich of densely woven fibers and resilient polymers—had performed exactly as designed. The incident converted me from skeptic to evangelist regarding protective footwear.

The Nail That Didn’t Stand a Chance

A subsequent incident proved even more impressive. Working on a deck refurbishment, I unknowingly stood on a board with an upturned nail for nearly twenty minutes. Only upon moving did I notice the three-inch fastener that had been pressing against my sole. The nail had barely dimpled the outsole material, demonstrating the remarkable puncture resistance of properly engineered footwear. My colleagues’ astonishment matched my own, particularly when I showed them the completely undamaged interior of my shoe.

Debris and Rough Terrain

Rocky Trails and Gravel Paths

The protective qualities of superior sneakers extend beyond construction hazards. An impromptu hike along a rocky stream bed demonstrated their versatility. Sharp stones and angular debris that would have bruised feet in lesser footwear became unnoticeable underfoot. The combination of rock plates, cushioned midsoles, and reinforced toe caps transformed treacherous terrain into manageable pathways. The shoes’ ability to neutralize irregular surfaces allowed me to focus on the journey rather than each careful step.

Navigating Urban Construction Zones

Urban environments present their own hazards. Construction zones scatter minute metal fragments, glass shards, and concrete dust across sidewalks. My protective sneakers proved equally adept at managing these minuscule threats. Their dense outsole patterns prevented tiny objects from lodging in tread grooves, while reinforced sidewalls rebuffed abrasive contacts with construction barriers. The shoes transformed uncertain urban navigation into confident striding, even through the most chaotic construction areas.

The Slippery Surface Challenge

Wet Floors and the Science of Traction

Perhaps the most impressive feature of advanced sneakers is their performance on slick surfaces. The microtexture of quality rubber compounds maintains friction even when wet, a property known as hysteresis. My shoes demonstrated this remarkably during an unexpected rainstorm that transformed a marble lobby into a potential skating rink. While others tiptoed cautiously, I maintained normal gait without concern. The sneakers’ specifically engineered tread pattern channeled water away from contact points, maintaining crucial surface connection despite the deluge.

Ice and Snow: The Ultimate Test

Winter conditions present the ultimate challenge for footwear traction. Traditional sneakers become virtually useless on ice and compacted snow. My protective pair, however, incorporated winter-specific compounds that remain pliable in cold temperatures. The rubber maintained grip on frozen surfaces where standard formulations would have hardened into slippery plastic. Additionally, the deep lug pattern captured snow rather than sliding across it, creating natural cleats with each step. The confidence these shoes provided during winter excursions was nothing short of revelatory.

Unexpected Sneaker Superpowers

Electrical Hazard Protection

I discovered another unexpected benefit while helping a friend with electrical work. My sneakers, I learned, incorporated electrical hazard protection—a feature borrowed from occupational safety footwear. The non-conductive materials reduced the risk of electrical current passing through the shoe to the ground. This fortuitous safety feature, though never actively tested, provided additional peace of mind when working near electrical systems. The integration of such specialized protection into everyday footwear exemplifies the multifaceted approach of modern sneaker design.

Chemical and Liquid Resistance

An accidental spill of wood stain demonstrated another hidden advantage. The hydrophobic upper materials caused the liquid to bead rather than absorb. A quick wipe removed the stain completely, leaving no trace or damage. This resistance extends to many household chemicals, preventing corrosive substances from penetrating to the foot. The chemical resilience represents another crossover from industrial safety footwear, protecting against hazards most consumers never consider until confronted with them.

The Importance of Proper Fit

How Ill-Fitting Shoes Compromise Protection

Even the most technologically advanced footwear fails if improperly fitted. Shoes that slide allow feet to impact interior surfaces, negating cushioning benefits. Excess space permits foot movement during lateral motions, compromising stability. Conversely, overly tight shoes restrict circulation and prevent natural foot flexion. My initial pairs suffered from improper sizing—too large in some dimensions, too constrained in others. The resulting discomfort distracted from the protective features, highlighting the holistic nature of footwear performance.

Finding Your Perfect Match

Discovering truly protective sneakers requires understanding one’s unique foot morphology. Beyond simple length and width measurements, factors such as arch height, heel volume, and midfoot circumference dramatically affect fit. Professional fitting services use pressure-mapping technology to identify ideal models for individual feet. My eventual solution involved slightly different sizes for each foot—a common situation rarely addressed in commercial footwear. The perfect fit transformed my experience, allowing the shoes’ protective features to function optimally without compromising comfort.

Maintenance: Extending the Life of Your Protective Footwear

Cleaning Techniques for Different Materials

Proper maintenance significantly extends the functional lifespan of protective footwear. Different materials require specific cleaning approaches. Mesh uppers benefit from gentle brushing and air drying rather than machine washing. Leather and synthetic overlays respond well to specialized cleaners that remove contaminants without degrading protective treatments. Outsoles require particular attention, as debris embedded in treads compromises traction. I developed a routine of compressed air cleaning followed by warm water and mild detergent, preserving both appearance and function.

Repairs and When to Replace

Even exceptional footwear eventually degrades. Understanding when to repair versus replace proves crucial for maintaining protection. Outsole wear beyond 50% thickness significantly compromises puncture resistance. Midsole compression—evidenced by permanent creasing and reduced cushioning—indicates degraded impact protection. Torn upper materials or separated seams create entry points for debris. My beloved sneakers have undergone multiple repairs, including professional regluing of separated components and replacement of worn insoles. However, I’ve established clear criteria for retirement when structural integrity becomes compromised.

Cost vs. Value: The Economics of Quality Footwear

The initial investment in truly protective footwear often exceeds triple the price of basic sneakers. This cost differential represents more than marketing—it reflects tangible differences in materials, construction techniques, and engineering. Premium materials like advanced rubber compounds and puncture-resistant membranes significantly increase manufacturing expenses. However, the extended lifespan often results in lower cost-per-wear than cheaper alternatives. More importantly, the prevented injuries and maintained productivity create value beyond simple durability. My experience suggests that quality protective footwear represents one of the most economically sound investments in personal equipment.

Beyond Protection: Style and Confidence

The psychological impact of dependable footwear extends beyond physical protection. Moving with confidence dramatically changes one’s approach to potentially hazardous environments. Rather than constant vigilance regarding foot placement, attention focuses on the task at hand. This cognitive freedom improves both efficiency and enjoyment. Additionally, modern protective sneakers have transcended their utilitarian origins to become style statements. My preferred pairs garner compliments despite their functional origins, demonstrating that protection and aesthetics need not be mutually exclusive.

Real-World Testing: My Most Challenging Experiences

The Flooded Basement Incident

A burst pipe created my most dramatic footwear test. Two inches of water covered a basement floor strewn with unseen debris from collapsed ceiling tiles. The combination of slippery surfaces and hidden hazards would have been treacherous in ordinary shoes. My protective sneakers maintained exceptional traction despite the standing water. Their waterproof uppers kept my feet completely dry, while puncture-resistant soles prevented several encountered nails from causing injury. The incident confirmed that laboratory-tested features translate directly to real-world protection.

The Mountain Trail Mishap

An impromptu detour during a mountain hike led to an unplanned descent down a steep, debris-covered slope. What began as a controlled descent quickly accelerated beyond comfortable speed. My sneakers’ aggressive lugs dug into loose material, providing crucial braking force. The reinforced toe caps deflected multiple impacts from exposed rocks. The ankle support prevented potential sprains during awkward landings. Most impressively, the shoes’ protective features performed flawlessly despite being pushed far beyond their intended use case. The experience solidified my appreciation for overengineered footwear.

Specialized Sneakers for Specific Environments

Workplace Safety Footwear

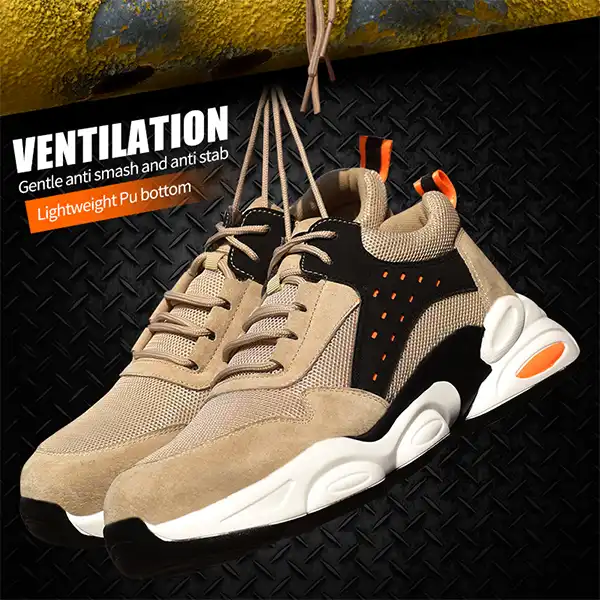

The boundary between athletic and occupational footwear continues to blur. Many workplaces now permit safety sneakers that meet protective standards while providing athletic shoe comfort. These hybrid designs incorporate features like metatarsal guards, puncture-resistant plates, and slip-resistant outsoles within sneaker-like silhouettes. Some include composite safety toes that meet workplace requirements without the weight and cold transfer of traditional steel. For those in specialized industries, these purpose-built designs offer certified protection without sacrificing mobility or comfort.

All-Terrain Adventure Shoes

Outdoor enthusiasts benefit from protection-focused trail shoes that incorporate many construction-grade features. These specialized designs include reinforced rand areas that resist abrasion from rocks and roots. Their outsoles feature aggressive, self-cleaning lug patterns that maintain traction in mud and loose debris. Waterproof membranes keep feet dry during stream crossings, while quick-drying materials prevent maceration during extended wet conditions. The convergence of outdoor recreation and protective technology has created a new category of footwear that excels in unpredictable environments.

The Future of Protective Sneaker Technology

Smart Shoes and Adaptive Materials

Emerging technologies promise even more sophisticated protection. Pressure-sensitive materials that instantly harden upon impact could provide dynamic protection that remains flexible during normal use. Embedded sensors might detect hazardous conditions—like electrical current or chemical exposure—and alert wearers through smartphone connectivity. Adaptive cushioning systems could adjust density based on terrain and gait patterns. These innovations represent the frontier of protective footwear, potentially revolutionizing how we interact with challenging environments.

Sustainability in Safety Footwear

The future of protective footwear must address environmental concerns while maintaining performance. Bio-based polymers derived from renewable resources have begun replacing petroleum-based compounds in outsole production. Recycled materials increasingly appear in structural components without compromising integrity. Modular designs allow replacement of worn components rather than entire shoes. These sustainability initiatives represent not just ecological responsibility but practical benefits—many bio-based materials offer superior performance characteristics compared to traditional compounds.